The SLA Challenger

Squaring the circle is now quite simple! Grow your business by utilizing FDR to achieve a remarkable balance between robustness and high accuracy. With this 3D printing technology you can build durable parts with:

- The high level of detail resolution typically associated with stereolithography (SLA)

- At the industrial production volume and pace of selective laser sintering (SLS)

The arrival of fine detail resolution (FDR) technology makes it possible to achieve a remarkable balance in polymer additive manufacturing (AM). Using FDR, you can build durable parts with the high level of detail resolution typically associated with stereolithography (SLA) at the industrial production volume and pace of selective laser sintering (SLS). Ensure your AM series production leads to parts as complex and detailed as your prototypes with FDR's cutting-edge system, and meet the demands of your most challenging industrial 3D printing applications.

Download the eGuide to familiarize yourself with fundamental design considerations and valuable 3D printing insights to leverage new fields of applications.

Exploring FDR vs SLA:

Key Features

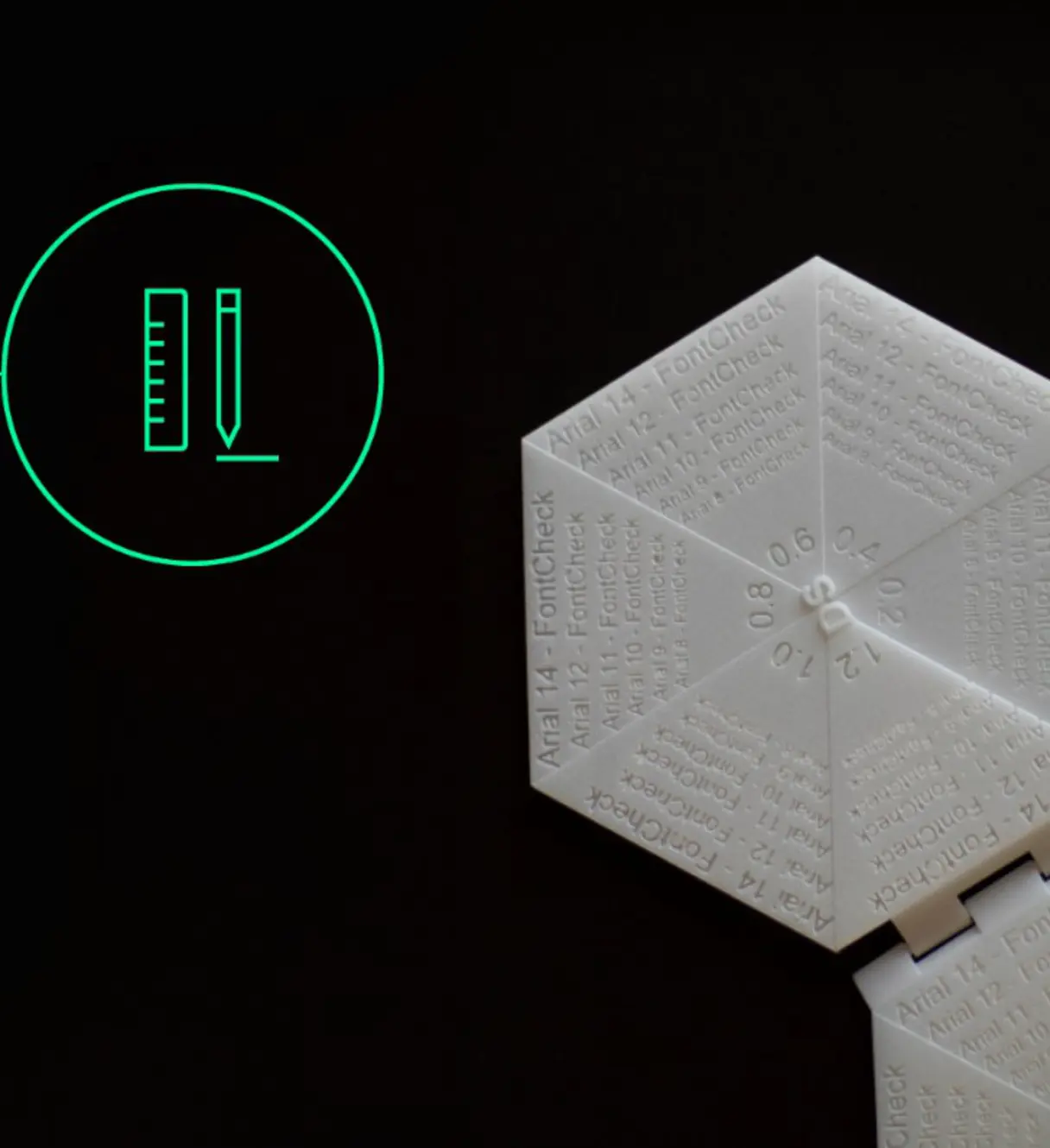

FDR is capable of part production volume comparable to SLS because the technologies are very similar; both are forms of laser powder bed fusion (LPBF). But FDR utilizes CO lasers that generate ultra-thin beams with a 0.22 mm (200 µm) focus diameter — about half the size of what's seen in SLS 3D printers. The ultra-fine laser allows for powder melting and shaping at the granular level necessary to create tiny part details: for example, detailed surface lettering and intricately shaped connectors on a microelectronic plug.

Meanwhile, fast but even powder application from the recoater ensures material densification, further contributing to part accuracy. Ultimately, depending on part geometry, FDR's margin of error for dimensional accuracy is just +/- 40µm, which matches injection molding. The precision FDR brings to part builds also comes with stability, robustness and durability — ideal for electrical and electronics equipment, special mechanical engineering and medical device manufacturing.

SLA, meanwhile, uses photopolymer resins stored in a reservoir or vat (hence one of the SLA variations being called "vat photopolymerization"). The build plate is initially atop the pool or resin and periodically submerges and surfaces. Ultraviolet (UV) laser light (instead of a CO laser beam seen in FDR) heats the photopolymer until it solidifies into multilayered shapes.

Parts produced using SLA technologies feature remarkably high resolution. This is the key reason why the technology remains part of the additive manufacturing universe. SLA machines are also typically smaller than industrial 3D printing systems, with some even being desktop size.

Design for Additive Manufacturing with FDR

Free eGuide

Why Choose FDR?

Major Benefits

1

Remarkable Detail and Dimensional Accuracy

The chief advantage of FDR is built into its full name. Alongside FDR's high resolution and impressive surface finishes, it boasts outstanding dimensional accuracy (+/- 40µm), so the technology also improves the odds of parts in a job coming out right the first time.

Non-LPBF AM technologies like SLA and digital light processing (DLP) — another polymer resin-based process — can produce similarly high-resolution results. But SLA and DLP parts function most effectively as proofs of concept or for experimental use. If production were scaled up to a volume necessary for industrial-level additive manufacturing, the detail resolution and dimensional accuracy of SLA and DLP would not be as reliably high.

2

Supportless Building

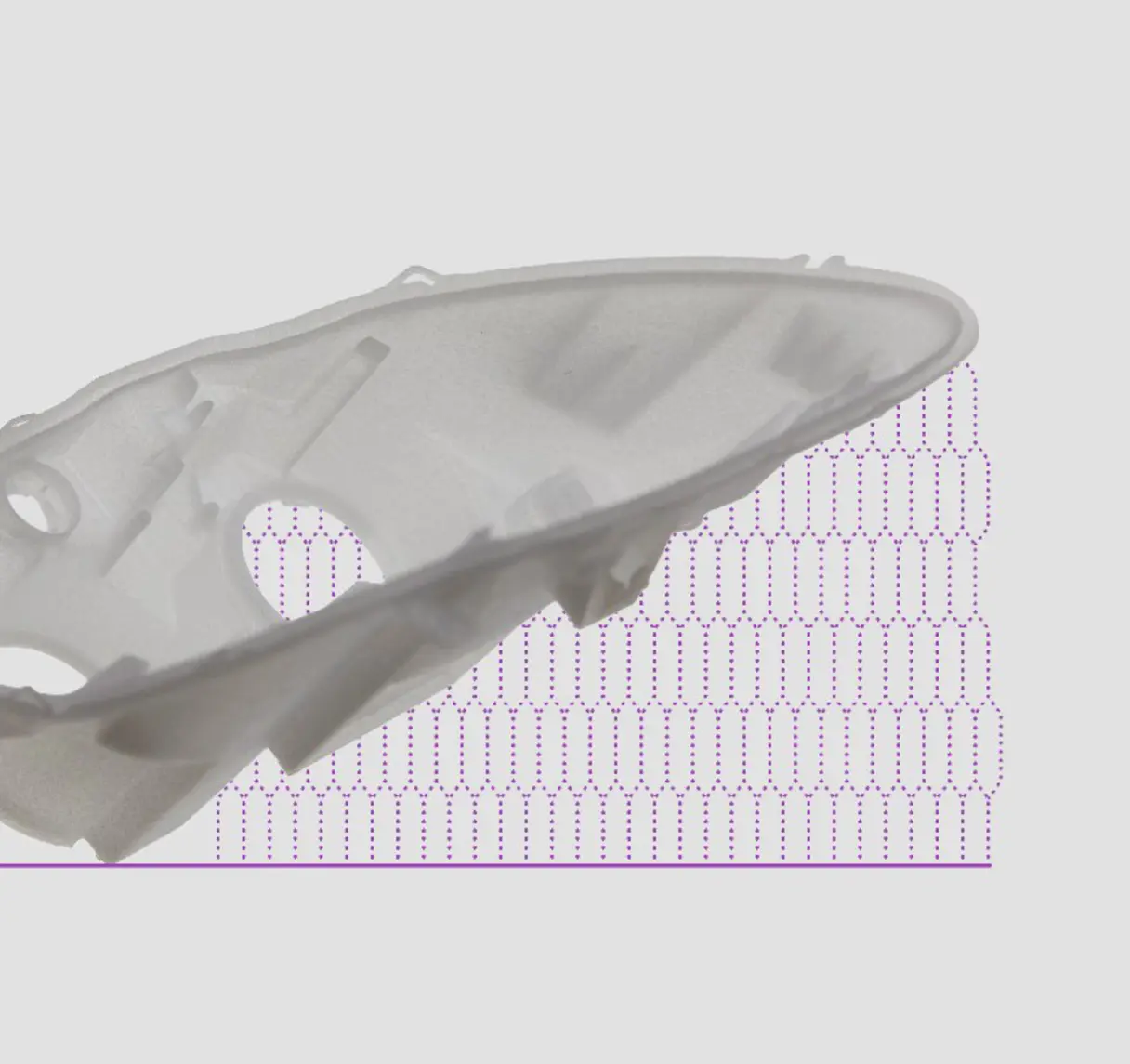

Various non-LPBF polymer 3D printing methods typically require support structures. In general, the entire part must be attached to the build plate during the build process to ensure the part stays in its intended player and the individual resin layers are applied where they should be. If the part has any overhangs or spans, these also need supports. Any necessary support structures must be accounted for during design, printed during the build and carefully removed afterward. This slows down production, post-processing and the overall AM process chain.

FDR — like SLS — doesn't require supports during part builds. The unfused powder particles are sufficient to hold the parts in place and support overhangs. This simplifies the design, eases placing of parts within the build volume, helps speed up post-processing and reduces material waste, while also enhancing part quality and increasing productivity — all without sacrificing detail.

3

Higher Productivity

The 3D printing methods that can match FDR for detail resolution, like SLA and DLP, can't approximate its production volume: This is due in large part to the slow build processes of these resin-based methods, which the relatively quick laser sintering of FDR can easily outpace.

Additionally, unlike SLA, FDR allows you to nest parts in multiple vertical levels (depending on part height) to take full advantage of the process chamber's height — not only its length and width. This contributes further to increased productivity.

4

Simplified Post-Processing

With SLA and DLP, individual parts must be delicately set aside for post-processing. Also, further exposure to laser energy or UV light is often required to harden parts produced via these methods, even those that will only be prototypes.

By contrast, FDR requires minimal post-processing: No UV or heat treatment is necessary, and there are no supports that must be removed.

5

Strong Mechanical Properties

FDR's remarkable capacity for detail resolution comes alongside high dimensional accuracy and excellent stability. The polymer used for FDR, polyamide 11 (PA 11), has outstanding mechanical properties: high impact resistance, high elongation at break and more. This ensures that FDR components can easily stand up to tough operating environments and be utilized as end-use parts.

6

Outstanding Long-Term Stability

SLA and DLP, as mentioned, have little trouble matching the detail of FDR, and their parts can be quite accurate. But the polymer resins featured in these processes are sensitive to UV light. As such, parts must be kept away from sunlight or any other source of light that contains UV radiation.

By contrast, the PA 11 used for FDR is strongly resistant to UV rays while being both chemically and mechanically heat-resistant. This helps strengthen the effectiveness and lengthen the life cycle of FDR-produced parts.

7

Sustainable, Responsible Material Use

Polymers vary widely on the spectrum of sustainability. Some are recyclable or otherwise material-efficient; others are much less so. PA 11 belongs in the former category. It's made entirely from castor beans, which grow on marginal lands not suitable for food crops, and it can be recycled. Also, while you wouldn't want to eat castor beans, the PA 11 made from them is biocompatible, making it useful for the medical field as well as products that come in contact with food.

By contrast, the photopolymer resins in SLA and DLP are toxic and require careful disposal procedures. During production, the resins produce unpleasant fumes and require you to wear gloves when handling them.

Introduce FDR into Your AM Workflow

One cannot necessarily say there is any "one size fits all" approach to polymer 3D printing. Though the disadvantages of SLA and DLP that we've pointed out are noteworthy, that doesn't mean they should be rejected out of hand. At the same time, it's worth noting that with FDR, you don't have to switch materials when you go from prototyping to production.

By combining the capability for intricate detail resolution with the industrial efficiency of SLS, FDR can be the centerpiece of your organization's polymer additive manufacturing operations, whether it's the only AM process you utilize or not. As EOS experts work to refine FDR technology and expand its compatibility to other materials, its range of available applications will only increase.

eGuide

Design for Additive Manufacturing with FDR

Download the eGuide to familiarize yourself with fundamental design considerations and valuable 3D printing insights to leverage new fields of applications.

This eGuide provides insights for both the well-versed, seasoned engineer and those just beginning their polymer 3D printing journey on how to:

- Leverage all essential design principles

- Export data without compromising part quality

- Perfectly orientate parts to minimize time, cost, and waste

- Bypass technology-inherent phenomena and common errors