PA 2200 Now Ready for

Why choose PA 2200?

-

The Only Food-Contact Compliant 3D Printing Material – Ensures full compliance with European regulations, providing a competitive edge.

-

Superior Mechanical Properties – Delivers strength, durability, and reliability for food-related production tools.

-

Simplified Compliance Process – Our documentation supports your end-product certification via official migration tests.

-

Expert Support – We provide detailed material ingredient information to laboratories upon request.

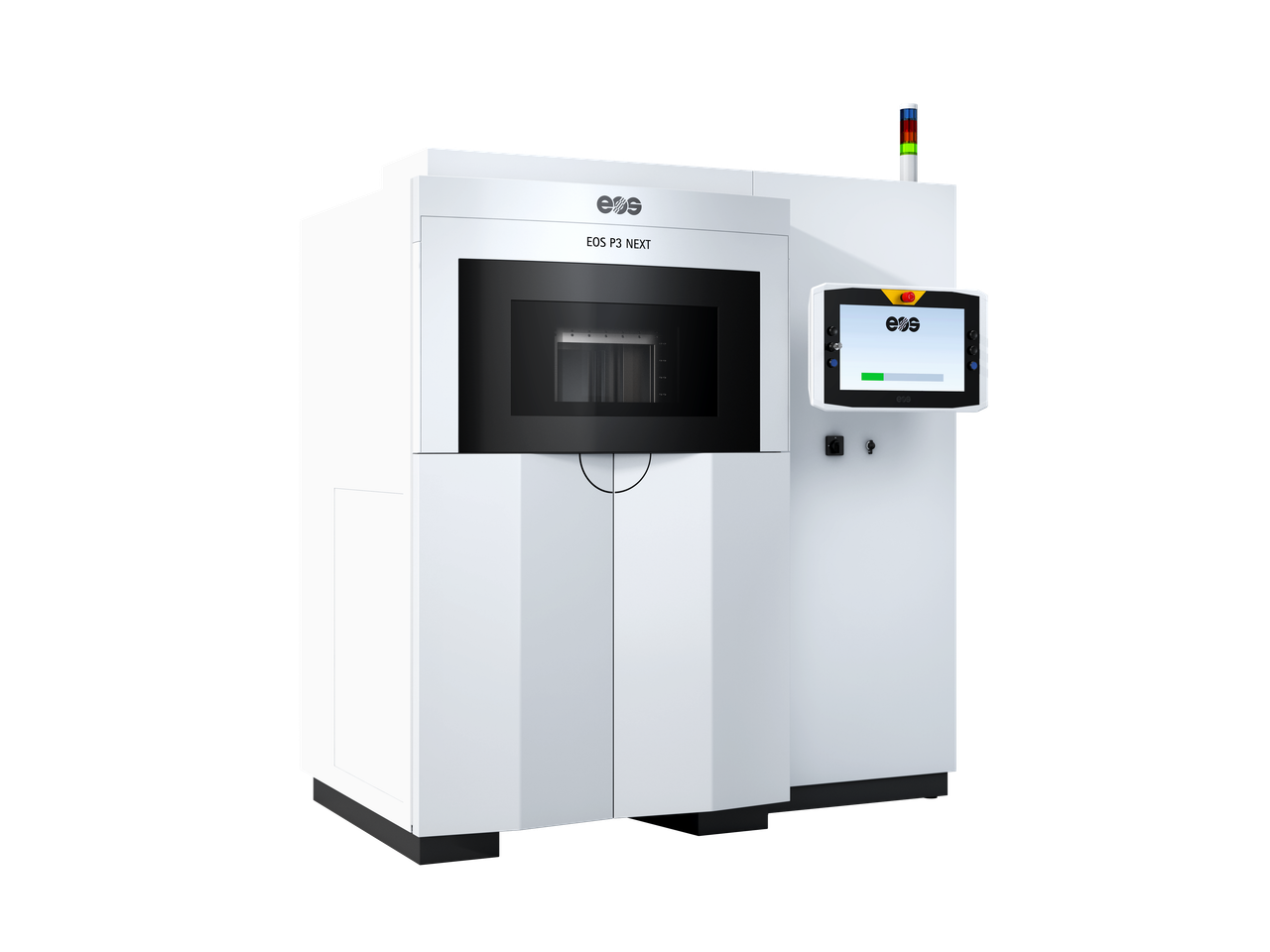

Boost Productivity with the EOS P3 NEXT

The latest EOS P3 NEXT is designed to maximize efficiency and performance in industrial 3D printing. Now featuring two innovative materials, this advanced system enhances production speed and cost-effectiveness.

Key Benefits of the EOS P3 NEXT

Pairing PA 2200 with the EOS P3 NEXT means you’re not just meeting industry standards - you’re staying ahead of them.

Take the Next Step and become a leader in food-safe 3D printing, unlocking new business potential. Learn how PA 2200 and the EOS P3 NEXT can transform your production capabilities.

Watch Our On-Demand Webinar

Explore the EOS P3 NEXT solution and see how this solution can transform your production process. Want to learn more?