Are You New to 3D Printing?

Welcome to additive manufacturing (AM). Let's find your 3D printing solution that fits your manufacturing needs.

Getting Started with AM

AM can unlock hidden potential within your business through lightweighting, part consolidation, and more.

There was a future in it. We could merge the engineering knowledge we have with the new industry and technology [for] an advantage to enter the market, rather than being another CNC shop down the road. It was a technology that needed innovation, and we were not short on that.

There was a future in it. We could merge the engineering knowledge we have with the new industry and technology [for] an advantage to enter the market, rather than being another CNC shop down the road. It was a technology that needed innovation, and we were not short on that.

EOS M 290 |

EOS M 300-4 |

BUILD VOLUME:

|

BUILD VOLUME:

|

MATERIALS:AluminumCase Hardening SteelCobalt ChromeCopperMaraging SteelNickel AlloyStainless SteelTitaniumTool Steel |

MATERIALS:

|

The Benefits of Metal AM

Metal additive manufacturing is an exciting and cutting-edge technology for many businesses, with early adopters like the aerospace and medical industry leading the way.

Make one product with titanium, another with aluminum. Don't let material limitations dictate your business.

Take a part that is traditionally made with 12 components and print it in one with industrial 3D printing design.

Alter your STL design and send to the 3D printer within minutes with your AM digital warehouse.

FORMIGA P 110 VELOCIS |

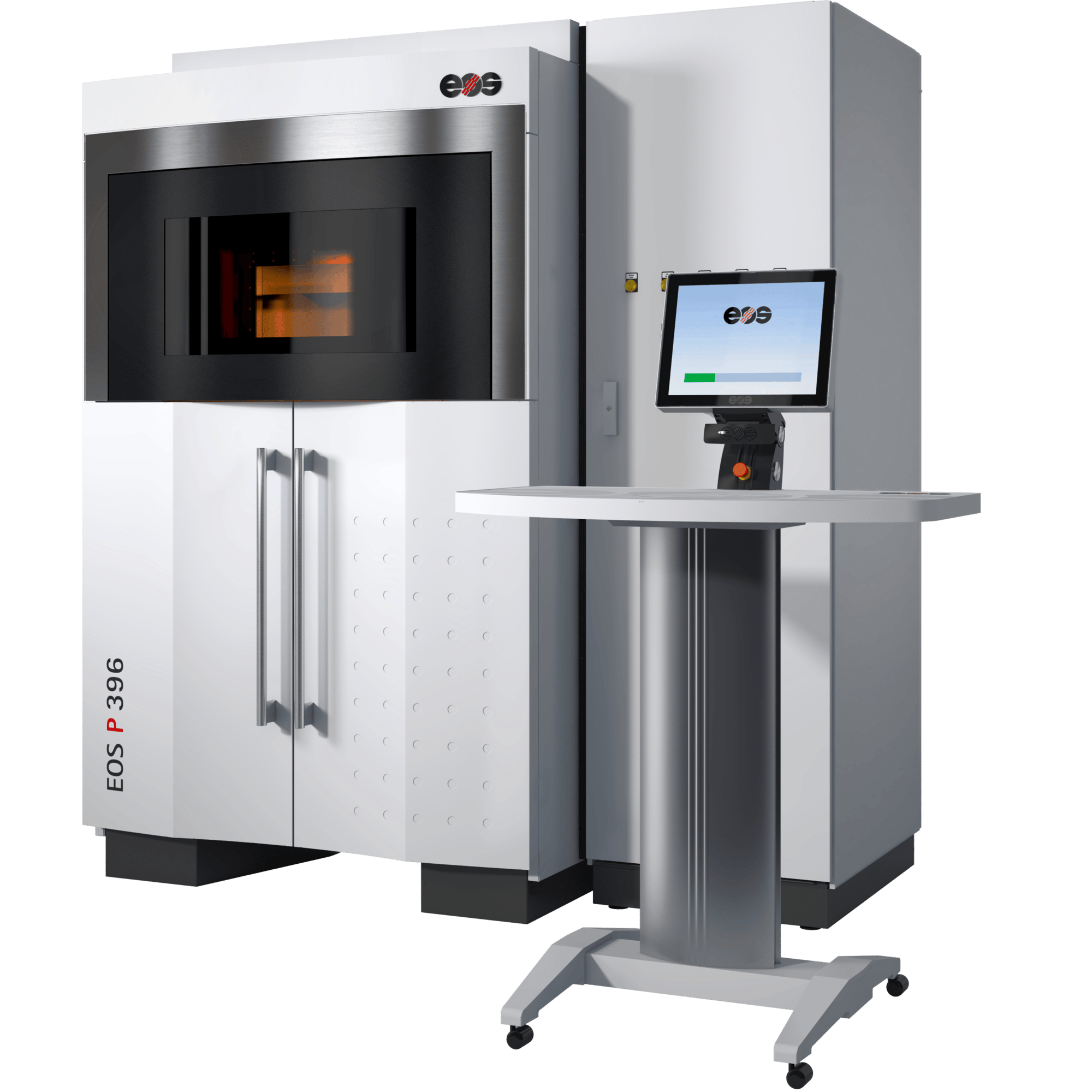

EOS P 396 |

BUILD VOLUME:250 x 250 x 330 mm(7.9 x 9.8 x 13 in)SCAN SPEEED:5 m/s (16.4 ft/sec) |

BUILD VOLUME:340 x 340 x 600 mm(13.4 x 13.4 x 23.6 in)SCAN SPEEED:6 m/s (19.7 ft/sec) |

MATERIALS:PA 2200 CarbonReducedPA 2200PA 2201PA 3200 GFAlumidePA 1101 ClimateNeutralPA 1101PA 1102 BlackEOS TPU 1301 |

MATERIALS:PA 2200 CarbonReducedPA 2200PA 2201 PA 2210 FR PrimePart FR PA 3200 GF PA 640 GSL AlumidePA 1101 ClimateNeutral PA 1101PA 1102 BlackHP 11-30FR 106 EOS TPU 1301 |

The Benefits of Polymer AM

Polymer 3D printing can be complex and confusing, but it doesn’t have to be. With the right resources, education, and application design, your business can successfully integrate AM into your next production line.

Make one application with Nylon 11, another with TPU. Don’t let material limitations dictate your business.

Take a part that is traditionally made with 12 components and print it in one with industrial 3D printing design.

Alter your STL design and send to the 3D printer within minutes at or in your AM digital warehouse.